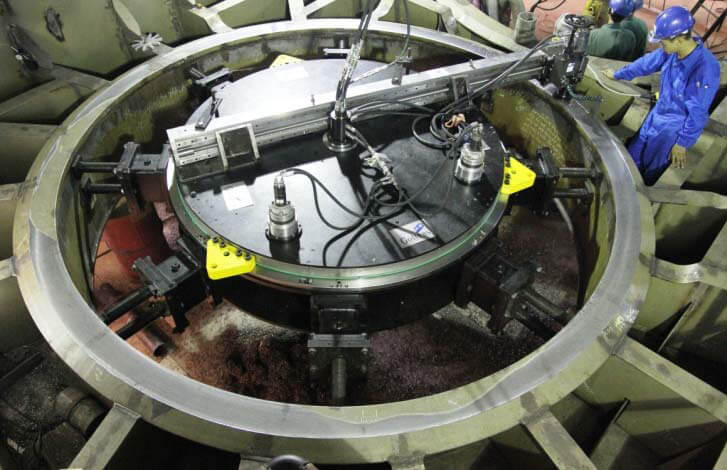

Kian marine ’ On-Site machining capability eliminates the logistical and cost related issues that go along with repairs and major replacements on any large equipment that is not easily moved.

Beyond in-place journal machining and line boring applications, Kian marine’ expert on-site machinists perform a broad spectrum of machining procedures including large scale flange facing, surface machining as well as addressing unique, one of a kind requirements with custom built tools.