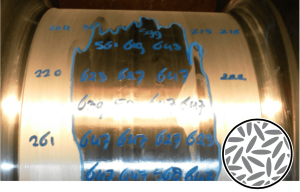

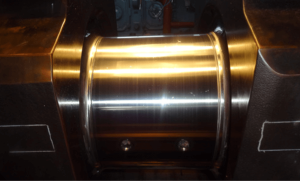

Historically the only option was to try and machine below the high crankshaft hardness, which very often resulted in a condemned shaft if the hardness extended below the rated diameter. Even if the machining was successful, a large amount of material generally needed to be removed from the shaft, limiting expected lifespan.

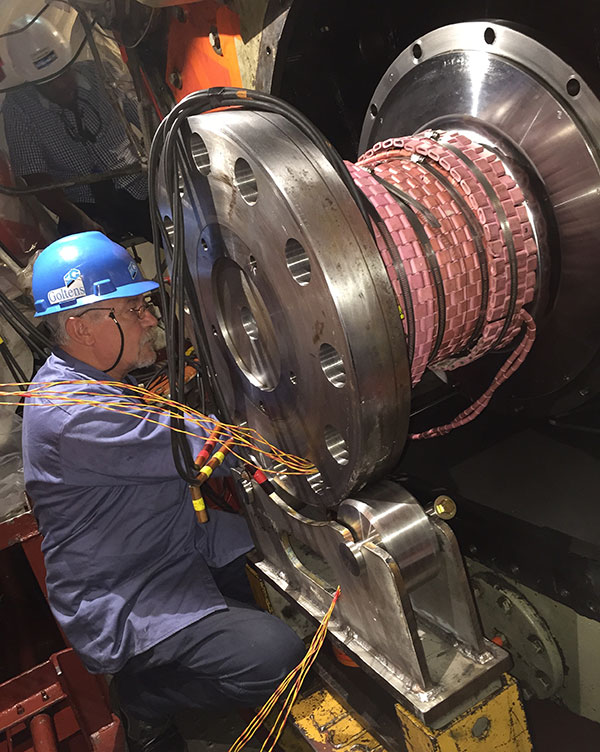

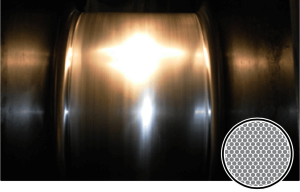

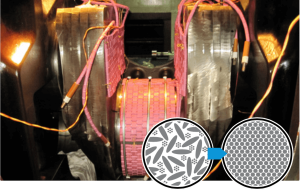

With in-situ annealing, the amount of material machined off the crankshaft is generally much less substantial, leaving significantly more material on the journal, which extends the life expectancy of the shaft. Kian marine’ process for annealing crankshafts and other shafting can be done successfully In-Situ (with the crankshaft in-place) as well as in our workshops around the world. A deep understanding of the metallurgy, expansion characteristics and safety precautions has been developed and refined over the years into a safe, repeatable, highly controlled process.