With the emissions control regulations in effect requiring the use of an exhaust gas scrubber system or the burning of low Sulphur fuel oil to meet emissions criteria, Kian marine is seeing an ever-increasing demand for liner wear inspections on 2-stroke main engines. Operators running on low Sulphur fuels are aware of the lower lubricity of these blends and the potential inconsistency of the bunkers they take on in various ports around the globe. Failure to follow OEM guidelines to correctly adjust the lube oil type and feed rate to account for the change in fuel type can result in accelerated wear patters due to over lubricating or under lubricating, resulting in bore polish or liner scuffing. Generally, cold corrosion results from operating at too low an operational temperature or using oil with too low of a Base Number (BN) and Bore Polish results from over lubrication use of oils with too high of a BN. Both of these conditions result in accelerated wear and lead to liner scuffing.

Increased Efficiency In Inspections

Traditionally these liner inspections were completed with the disassembly of the unit inclusive of cylinder covers and piston assemblies. The process was time consuming, required a team of technicians and limited the number of liners that could be inspected in a given day.

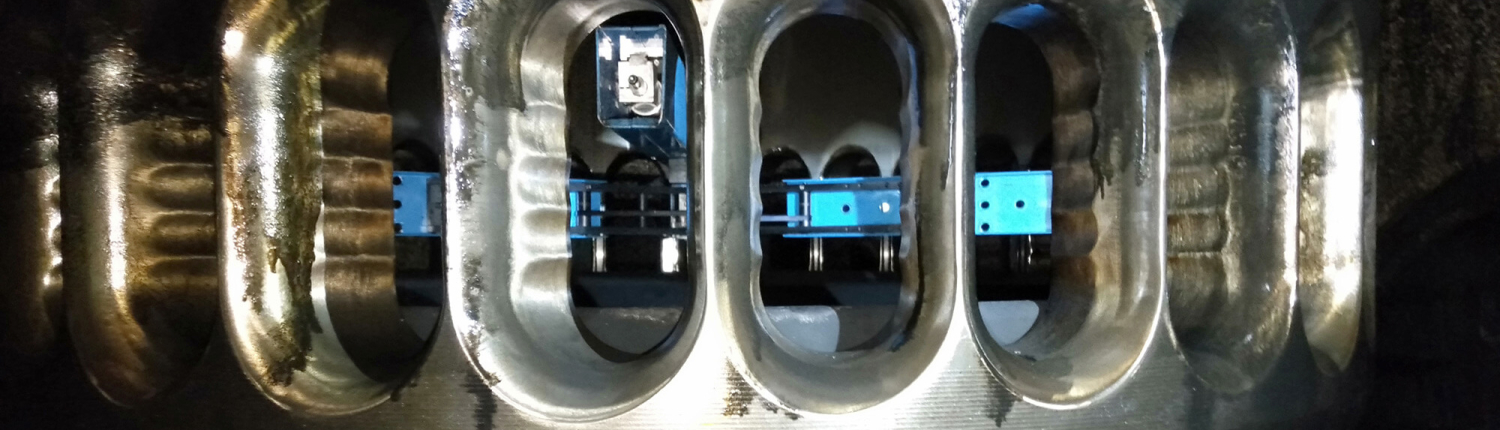

In response to the growing demand, and to introduce higher efficiencies to the inspections, Kian marine has invested globally in the LDM (Liner Diameter Measurement) tooling from Chris Marine. With the LDM, Kian marine is now able to undertake the inspection of all liners on a 2-stroke main engine in a single day without disassembly of the unit and produce highly accurate reports to indicate cylinder liner wear, remaining life of the liner, ovality and any clover leafing present.

Knowledge Leads To Efficient Action

The results provide the operator with a highly accurate picture of the condition of their liners and allow them to proactively plan for replacement of the liners, take corrective action or operate confidently with the knowledge that their liners are aging properly. In addition to the avoidance of unexpected off-hire periods due to unexpected failure, operators are able to use the data to determine which liners are to be replaced during upcoming yard periods and arrange for purchase and transport in the most economical manner. Kian marine is engaging with some customers who are planning to perform LDM checks on their entire fleet on a periodic basis as part of proactive, condition monitoring program.

Kian marine stations in Singapore, China, Dubai, Rotterdam, Houston and Miami are all capable of delivering this service.

The measurement process is simple:

- Calibrate the system

- Put the piston in its lowest position

- Attach the piston height measurement device to the underside of the piston

- Insert the measurement device and place it on top of the piston

- Move the piston to desired position and carry out the predefined number of diameter readings

- Move piston to next position and measure diameters again

- Continue until finished

- Evaluate the measured data in the handheld terminal or transmit measurement data to a PC for

- further evaluation, storage or report generation

Liner Measurement Parameters:

- 2-Stroke Engines:

- Range: 500-980 mm diameters

- Removal of Cylinder cover is not required for liner diameter measurement

- Measurement tools can be inserted through the scavenging ports to perform job

- 4-Stroke Engines:

- Range: >500mm

- Cylinder cover must be removed to complete measurements